ຈຸດຜະລິດຕະຫລາດ Drip

ສົ່ງສອບຖາມ

ກະດານແປໄຟ emitter emitter emitter ວັດຊົນລະປະທານ

ລັກສະນະ:

ຈຸດຜະລິດຕະຫລາດ Drip

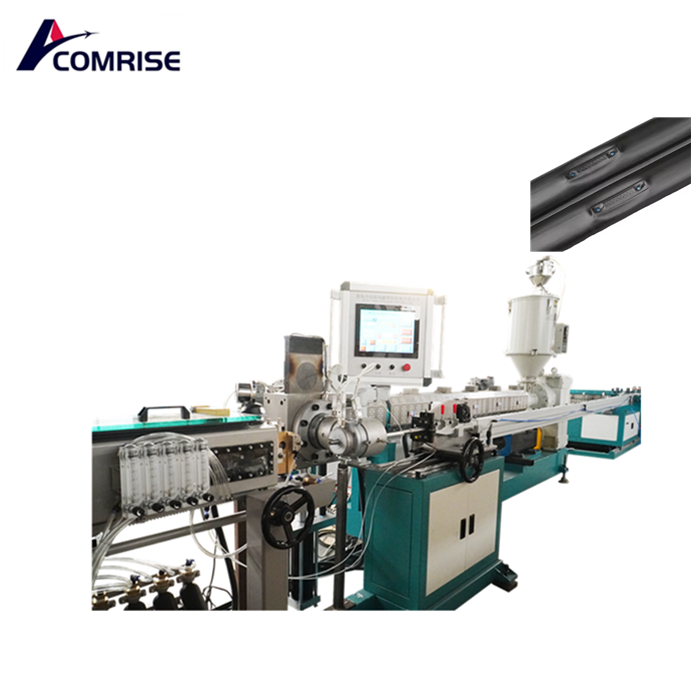

1. Dropper ແມ່ນການສີດພົ່ນລົງໃນຫນຶ່ງໄປແລະມີຊ່ອງທາງທີ່ກ້ວາງແລະຍາວ. ມັນເຮັດຫນ້າທີ່ເປັນປ່ອງຢ້ຽມຕົວກອງແລະມີການປະຕິບັດການອຸດຕັນທີ່ແຂງແຮງ.

2. ຄວາມເປັນເອກະພາບທີ່ດີຂອງຜົນຜະລິດນ້ໍາ. ຫົວ drint ແມ່ນເຊື່ອມຢູ່ໂດຍກົງກັບທໍ່ທໍ່ຊົນລະປະທານ drip, ຫຼຸດຜ່ອນການສູນເສຍຄວາມກົດດັນແລະການປະຢັດນ້ໍາ.

3. ມັນສາມາດບັນລຸການນໍາໃຊ້ນ້ໍາແລະປຸຍພ້ອມກັນ, ປັບປຸງປະສິດທິພາບຂອງຝຸ່ນ

4. ການຮັບຮອງເອົາຊ່ອງທາງໄຫຼເຂົ້າດ້ວຍຜົນກະທົບໃນການຊົດເຊີຍຄວາມກົດດັນທີ່ແນ່ນອນ.

.. Dropper ແມ່ນປະສົມປະສານກັບທໍ່ສົ່ງ, ງ່າຍຕໍ່ການຕິດຕັ້ງແລະໃຊ້, ຕົ້ນທຶນຕ່ໍາ, ແລະການລົງທືນຕໍ່າ.

6. Drip ທໍ່ສະເພາະທີ່ແຕກຕ່າງກັນແມ່ນເຫມາະສົມກັບສະຖານະການຊົນລະປະສາດທີ່ແຕກຕ່າງກັນ,

ໄລຍະຫ່າງລະຫວ່າງ dripper ແລະສາມາດປັບໄດ້ຕາມຄວາມຕ້ອງການຂອງພືດທີ່ແຕກຕ່າງກັນເພື່ອຕອບສະຫນອງລູກຄ້າທີ່ແຕກຕ່າງກັນ.

ການຄັດເລືອກຫົວ, ການຖ່າຍທອດ, ຫນ່ວຍງານຝັງ

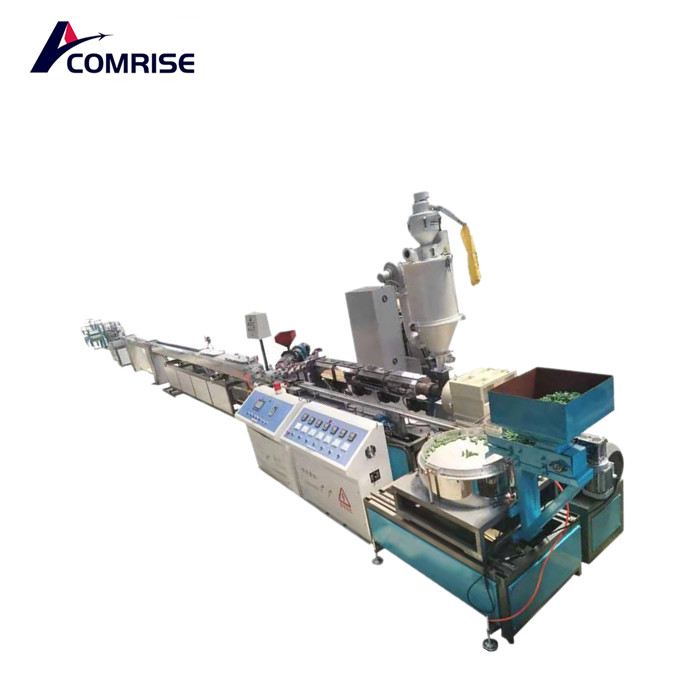

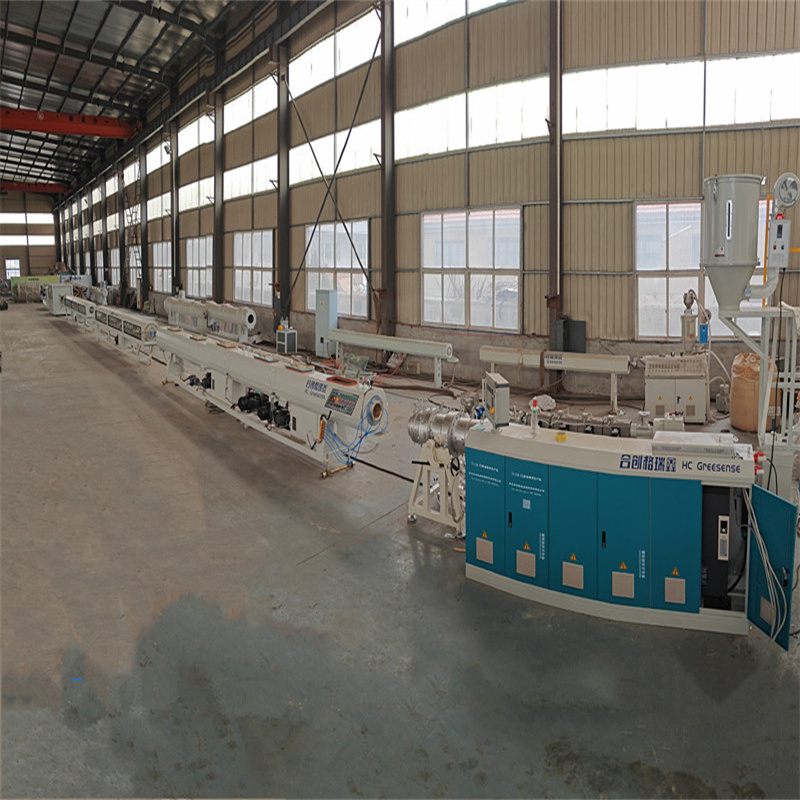

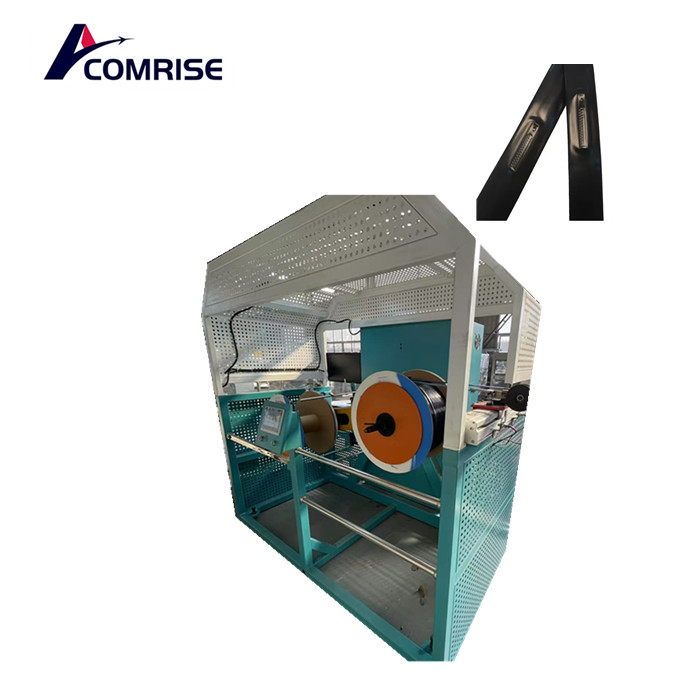

ເຄື່ອງຜະລິດທໍ່ນ້ໍາເປື້ອນມີເສັ້ນຜ່າກາງ 1580 ມມແລະເຂົ້າກັນໄດ້ກັບທັງສອງສ່ວນໃຫຍ່ແລະນ້ອຍໆ. ພວກເຮົາໄດ້ປັບປຸງການປັບປຸງຂະບວນການການຮັບຮູ້ການຮັບຮູ້ທີ່ເປັນໂຣກ pneumatic, ການຄວບຄຸມຄວາມຖີ່.

ຄວາມໄວໃນການຮັບຮູ້: ຢອດເມັດ <2500.

ຂະຫນາດຫົວທີ່ໃຊ້ໄດ້: 23mm * 6mm * 2.1mm, ການຖ່າຍທອດຄວາມໄວ> 3000 ຊິ້ນ / ນາທີ / ນາທີ / ນາທີ

ສາມາດປັບຕົວເຂົ້າກັບຄວາມຍາວທີ່ເຫມາະສົມຂອງປີ 18mm-20-23-24-25-27-6-27-30

screruder screruder screrub-90/33 ALCTW Screwler Screwler (90) SCTRE (90)

ເຄື່ອງວັດແທກທໍ່ສົ່ງນ້ໍາຖ້ວມສູງສຸດ: 180kg / h.

ມັນສາມາດປັບຕົວເຂົ້າກັບການຜະລິດວັດຖຸດິບແລະການຜະລິດວັດສະດຸທີ່ໃຊ້ແລ້ວ 90%.

ມໍເຕີ: 75kW Huichuan Servo ຫຼື Guomao + Huichuan Servo Controller

ໂດຍມີເຄື່ອງສົ່ງຄວາມກົດດັນ, ໂດຍບໍ່ມີເຄື່ອງລະຫັດສີ.

ຊຸດຂອງຜູ້ປ່ຽນຫນ້າຈໍໄຮໂດຼລິກແບບເຄິ່ງອັດຕະໂນມັດເຄິ່ງອັດຕະໂນມັດ

Gearbox: (Guomao ຫຼື Jiangzi). ແບບ (250).

ນ້ໍາອຸ່ນຄວາມເຢັນສະແຕນເລດ

ຄວາມຍາວ 4 ແມັດ

ລວມທັງອຸປະກອນແປຮູບທີ່ຕິດພັນກັບ dropper

ລວມທັງລະບົບການຜະລິດຄວບຄຸມການຜະລິດລາຍະການ

ລວມທັງອຸປະກອນກວດພົບ Pinhole ແລະ Hole

ລວມທັງອຸປະກອນຊອກຫາທໍ່ທີ່ແຕກຫັກ

ຖັງເກັບນ້ໍາເຢັນສະແຕນເລດ

ເສັ້ນຜ່າກາງທໍ່: φ16mm

ຄວາມຍາວທັງຫມົດຂອງການຫລົ້ມຈົມ: (6) ແມັດ

ສະແຕນເລດ 304 ອຸປະກອນການ, ຄວາມສູງທີ່ສາມາດປັບໄດ້

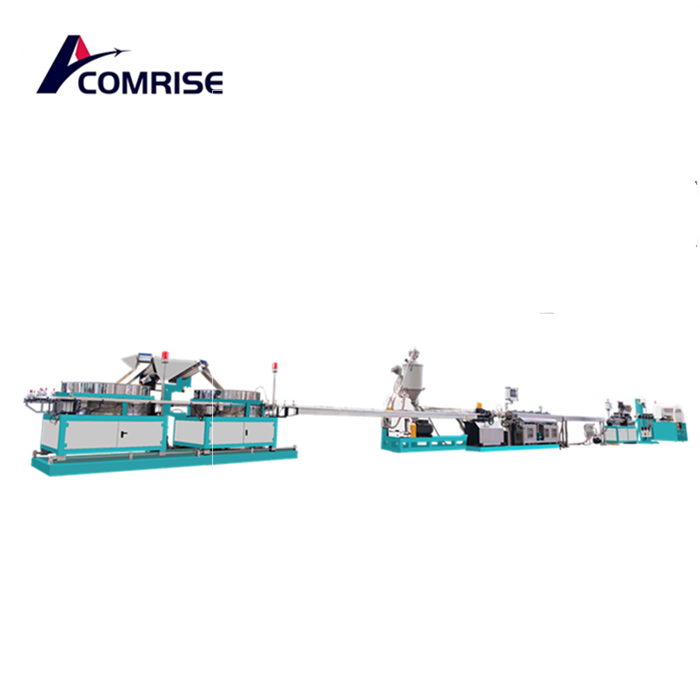

ເຄື່ອງຈັກ hauling

ການຕິດສາຍແອວ Synchronous Double Synchronous, ການຫນີບ pneumatic

ການຄວບຄຸມມໍເຕີ Panasonic Serage Servo, ພະລັງງານມໍເຕີ 3.0kW

ຄວາມໄວຂອງການພົວພັນ: 0-450m / min

ສະຖານີພະລັງງານລົມແບບອັດຕະໂນມັດ

ເຄື່ອງຜະລິດຕະຫຼອດທໍ່ການຜະລິດວັດແທກປະເທດຊົນປະທານອັດຕະໂນມັດສໍາລັບລອກທໍ່.

2.0kW * 2 ຍີ່ຫໍ້ servo motor: Panasonic

ຄວາມໄວສູງສຸດຂອງ 450 ແມັດຕໍ່ນາທີ

ຂັ້ນຕອນຕໍ່ໄປແມ່ນອັດຕະໂນມັດ

ເຈົ້າພາບ: Huichuan servo ຫຼື guomao; Siemens PLC; Siemens ສໍາພັດຫນ້າຈໍ; ຜູ້ຕິດຕໍ່ Schneider ແລະ Relay; servos ອື່ນໆ: ຍີ່ຫໍ້ Panasonic.

ຫນ້າທີ່ເຕືອນໄພສໍາລັບການຕັ້ງຄ່າສາຍການຜະລິດ: ການກະຕຸ້ນເຕືອນດ້ານການຜະລິດ, Pinhole ແລະ Pinhole ແລະການເຕືອນໄພຫົວ, ການເຕືອນໄພການຂາດແຄນທໍ່, ການກວດພົບຄວາມຜິດພາດຂອງທໍ່, ເຈາະຄວາມຜິດພາດ.

ກົດປຸ່ມ Start ກົດຫນຶ່ງຄັ້ງ, ຟັງຊັນການຕັດຄັດໃຫມ່ອັດຕະໂນມັດ, ສາມາດບັນລຸການເລີ່ມຕົ້ນໂດຍໄວໂດຍຄົນຫນຶ່ງ, ຫຼຸດຜ່ອນສິ່ງເສດເຫຼືອ.

ການສະແດງຫນ້າຈໍ Dual Camera Camera

ພວກເຮົາໄດ້ປັບປຸງຂະບວນການຜະລິດຂອງພວກເຮົາແລະຍົກລະດັບເຕັກໂນໂລຢີຂອງພວກເຮົາ. ເປັນໂຮງງານຜະລິດເຄື່ອງຈັກອັນດັບຫນຶ່ງໃນປະເທດຈີນ, ພວກເຮົາຈະພະຍາຍາມກ້າວໄປຂ້າງຫນ້າ

ໄດ້ຮັບວົງຢືມດຽວນີ້